Suck, Bang, Blow?

If you remember last week, we found that the timing is right on and that the valves are within spec. But the bugger still won't start. And no, going out for ice cream then trying again when we get back doesn't work. We've tried it. Twice. So today we are moving on to a spark test and a compression test. While spark is normally the first thing you would check, this was a special case. Because it had started and ran for about ten minutes before it just stopped, we were concerned that the timing had jumped. And since we had the head off anyway, we figured it couldn't hurt to check the timing and the valve clearance. So if it seems like we're a little out of order, that's why. So to check the spark I got out my spark gap tester. This tool is used to check the amount of power at the spark plug by measuring the length of the spark. It plugs into the spark plug wire boot (we talked about that on last week's Anatomy of an ATV about the ignition coil.) and clips on to the frame for ground. To check for spark, press the ignition button and watch for the spark to appear in the gap. A 20 mm spark is what the average spark on the KFX should be. We have more than 30 mm so we are good in that area.

If you remember last week, we found that the timing is right on and that the valves are within spec. But the bugger still won't start. And no, going out for ice cream then trying again when we get back doesn't work. We've tried it. Twice. So today we are moving on to a spark test and a compression test. While spark is normally the first thing you would check, this was a special case. Because it had started and ran for about ten minutes before it just stopped, we were concerned that the timing had jumped. And since we had the head off anyway, we figured it couldn't hurt to check the timing and the valve clearance. So if it seems like we're a little out of order, that's why. So to check the spark I got out my spark gap tester. This tool is used to check the amount of power at the spark plug by measuring the length of the spark. It plugs into the spark plug wire boot (we talked about that on last week's Anatomy of an ATV about the ignition coil.) and clips on to the frame for ground. To check for spark, press the ignition button and watch for the spark to appear in the gap. A 20 mm spark is what the average spark on the KFX should be. We have more than 30 mm so we are good in that area.  Once we knew that we had plenty of spark, we were able to move on to test the compression. You will need a compression tester for this, as well as the right adapter to fit the spark plug hole.

Once we knew that we had plenty of spark, we were able to move on to test the compression. You will need a compression tester for this, as well as the right adapter to fit the spark plug hole.  I have seen some homemade adaptors made out of an old spark plug but since most adaptors are available for $10 to $20, unless you absolutely have to have one right that second, it really doesn't seem worth it to make one. Luckily, I had the right adaptor. So I put the hose on the gauge and the adaptor on the hose.

I have seen some homemade adaptors made out of an old spark plug but since most adaptors are available for $10 to $20, unless you absolutely have to have one right that second, it really doesn't seem worth it to make one. Luckily, I had the right adaptor. So I put the hose on the gauge and the adaptor on the hose.  Then I carefully screwed the compression tester into the spark plug hole.

Then I carefully screwed the compression tester into the spark plug hole.  Now to run the test, I needed to make sure that engine was turning over fast enough. To do this I put some jumpers to another battery just to make sure.

Now to run the test, I needed to make sure that engine was turning over fast enough. To do this I put some jumpers to another battery just to make sure.  So now I just cranked the engine over holding the throttle wide open. And you look for the needle to jump up to whatever the spec is from the user manual. As you can see, the gauge did not move at all so our compression was less than 25 psi.

So now I just cranked the engine over holding the throttle wide open. And you look for the needle to jump up to whatever the spec is from the user manual. As you can see, the gauge did not move at all so our compression was less than 25 psi.  That’s not good. Now there are about three things that could cause the compression to be low. The valves could not be seating right but since these are brand new valves and seats, it's unlikely that is our problem. Or, the valves could be out of adjustment and the cam could be holding them open all the time; however, we checked the valve clearance last week and it was good. That leaves us with option number three, which is also most likely - the piston rings or cylinder wall is worn out. Well just what I wanted to have, another tear down post. But this is just one of the joys of ATV ownership. (I do love it)

That’s not good. Now there are about three things that could cause the compression to be low. The valves could not be seating right but since these are brand new valves and seats, it's unlikely that is our problem. Or, the valves could be out of adjustment and the cam could be holding them open all the time; however, we checked the valve clearance last week and it was good. That leaves us with option number three, which is also most likely - the piston rings or cylinder wall is worn out. Well just what I wanted to have, another tear down post. But this is just one of the joys of ATV ownership. (I do love it)

-

Original price $ 159.99 - Original price $ 204.99Original price$ 159.99 - $ 204.99$ 159.99 - $ 204.99Current price $ 159.99

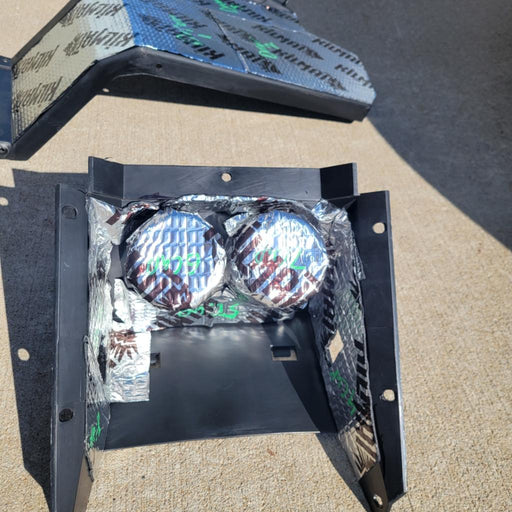

Air Filter Relocation Kit for ODES UTVS

Scooter's PowersportsIn stockOur very own Air Filter Relocation kit for ODES UTVS. Designed and manufactured by Scooter's Powersports. Unlike some ODES Air Filter Relocation K...

View full detailsOriginal price $ 159.99 - Original price $ 204.99Original price$ 159.99 - $ 204.99$ 159.99 - $ 204.99Current price $ 159.99 -

Original price $ 40.00 - Original price $ 40.00Original price$ 40.00$ 40.00 - $ 40.00Current price $ 40.00

Voltage Regulator Relocation Kit for ODES UTVS

Scooter's PowersportsDesigned to move the voltage regulator from under the hood to under the seat. Requested by you and built by Scooter's Powersports. Allows for elimi...

View full detailsOriginal price $ 40.00 - Original price $ 40.00Original price$ 40.00$ 40.00 - $ 40.00Current price $ 40.00 -

Original price $ 129.99 - Original price $ 159.99Original price$ 129.99 - $ 159.99$ 129.99 - $ 159.99Current price $ 129.99

Pre-Cut Sound Proof Matting for ODES UTVS

Scooter's PowersportsIf the noise inside the cab of your ODES UTV has ever bothered you, this. is your solution. Now you can get one of our best selling shop services a...

View full detailsOriginal price $ 129.99 - Original price $ 159.99Original price$ 129.99 - $ 159.99$ 129.99 - $ 159.99Current price $ 129.99 -

View all ODES UTV Performance mods

View all ODES UTV Performance mods

-

ODES UTVS best sellers

ODES UTVS best sellers -

Original price $ 38.49 - Original price $ 55.99Original price$ 38.49 - $ 55.99$ 38.49 - $ 55.99Current price $ 38.49

ODES Oil Change Kit for 800 and 1000 Engines

Scooter's PowersportsODES Industries recommends an engine oil change at 25-hours of run time or 1000 miles. (We won’t tell if you turn that down to once every 50-hours ...

View full detailsOriginal price $ 38.49 - Original price $ 55.99Original price$ 38.49 - $ 55.99$ 38.49 - $ 55.99Current price $ 38.49 -

Original price $ 7.99 - Original price $ 7.99Original price$ 7.99$ 7.99 - $ 7.99Current price $ 7.99

ODES Oil Filter - High-Performance

Not specifiedHigh-performance aftermarket ODES oil filter. Compatible with 800cc and 1000cc ODES engines. Be sure to select your make and model before adding to...

View full detailsOriginal price $ 7.99 - Original price $ 7.99Original price$ 7.99$ 7.99 - $ 7.99Current price $ 7.99 -

Original price $ 49.99 - Original price $ 62.00Original price$ 49.99 - $ 62.00$ 49.99 - $ 62.00Current price $ 49.99

Pivot Works Wheel Bearing Kit for ODES - Lifetime Replacement!

Pivot WorksIn stockPivot Works wheel bearing kit for 2012+ 800cc and 1000cc UTVs from ODES Industries. Fitment includes the Short Travel (Standard) suspension and the...

View full detailsOriginal price $ 49.99 - Original price $ 62.00Original price$ 49.99 - $ 62.00$ 49.99 - $ 62.00Current price $ 49.99 -

Original price $ 159.99 - Original price $ 204.99Original price$ 159.99 - $ 204.99$ 159.99 - $ 204.99Current price $ 159.99

Air Filter Relocation Kit for ODES UTVS

Scooter's PowersportsIn stockOur very own Air Filter Relocation kit for ODES UTVS. Designed and manufactured by Scooter's Powersports. Unlike some ODES Air Filter Relocation K...

View full detailsOriginal price $ 159.99 - Original price $ 204.99Original price$ 159.99 - $ 204.99$ 159.99 - $ 204.99Current price $ 159.99 -

Original price $ 40.99Original price $ 40.99 - Original price $ 40.99Original price $ 40.99Current price $ 36.95$ 36.95 - $ 36.95Current price $ 36.95

ODES 800cc Air Filter | 21040401001

ODES IndustriesOut of stockOEM air filter for ODES 800cc engines. Vehicle Fitment This part is compatible with the following vehicles 2012+ ODES Dominator 800 2015+ ODES Dom...

View full detailsOriginal price $ 40.99Original price $ 40.99 - Original price $ 40.99Original price $ 40.99Current price $ 36.95$ 36.95 - $ 36.95Current price $ 36.95Sold out -

Original price $ 18.99 - Original price $ 18.99Original price$ 18.99$ 18.99 - $ 18.99Current price $ 18.99

Fast Boot Kit

MooseIn stockExtremely heavy duty CV boot that fits virtually all ATVs and UTVs. Additional rib to allow boot to expand for larger joints Improved clamp retain...

View full detailsOriginal price $ 18.99 - Original price $ 18.99Original price$ 18.99$ 18.99 - $ 18.99Current price $ 18.99 -

Original price $ 29.99 - Original price $ 29.99Original price$ 29.99$ 29.99 - $ 29.99Current price $ 29.99

ODES Ball Joint Kit

Scooter's PowersportsODES ball joint kit for 800cc and 1000cc ODES UTVs. ODES Ball Joint Kit Includes (1) Ball joint (1) Circlip (1) Cotter pin (1) Nut Each kit provi...

View full detailsOriginal price $ 29.99 - Original price $ 29.99Original price$ 29.99$ 29.99 - $ 29.99Current price $ 29.99