Anatomy of an ATV: Wheel Bearings

System

Drive

Commonly Located

On an independent suspension, wheel bearings are located inside the spindle or steering knuckle. Each steering knuckle connects the wheel hub to the upper and lower A-Arms, with the CV shaft passing through the bearings inside the knuckle and into the wheel hub. On units with a solid rear axle; i.e, a 2001 Yamaha Warrior 350, the rear wheel bearings sit inside a single rear wheel hub. The solid axle connects to the wheel collar (which is bolted to the wheel), passes through the bearings located inside the wheel hub, through the sprocket collar (which holds the rear sprocket), and connects to the wheel collar on the opposite wheel.

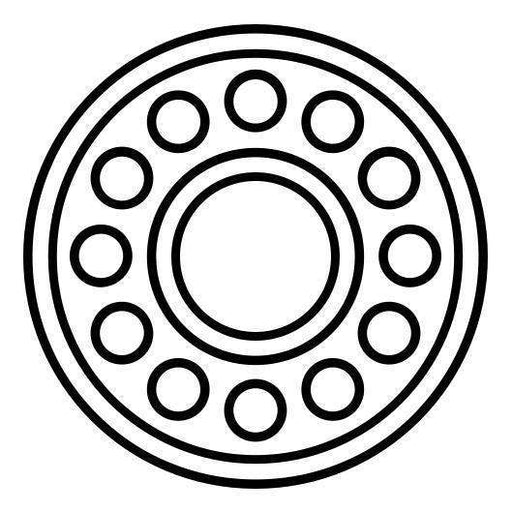

Physical Description

The powersports industry uses many types of wheel bearings, but the most common is a round stainless steel ring with ball bearings sealed on the inside. Many (but not all) aftermarket wheel bearing kits include oil seals. Oil seals can also vary in appearance. The most common is a thick round rubber seal. Certain aftermarket kits may provide oil seals that appear different than OEM oil seals; i.e., a round metal base with a flanged rubber flap. While these seals may exhibit a different appearance, they often perform the same function at OEM or better quality.

Functions

The wheels on the vehicle are brought to movement by forces generated by the engine. The engine passes these forces to the transmission, which passes them to either a differential or a sprocket. In either case, the end result is that this force is transferred to the axle which results in axle rotation. This rotation is the first visible sign of the force which causes the wheels to turn.

To turn the wheels, the axle must pass through the stationary steering knuckle or rear wheel hub assembly. It is important to note that neither the steering knuckle nor the rear wheel hub assembly have any relevance on whether or not the wheels turn. In this instance, these parts are only relevant as a carrier for the wheel bearings.

Because the carrier is incapable of rotation, wheel bearings are pressed inside a hub, allowing the rotation from the axle to transfer to the wheel hub and thus the wheel. During axle rotation, the outer ring of the wheel bearing remains stationary, as it maintains contact with the inner hub of the carrier. The inner ring, which is in contact with the axle, is free to rotate with the axle. This movement is made possible by the bearings sandwiched between the inner and outer rings.

The short service life of wheel bearings is due in part to the enormous pressure placed on the bearing. Note that wheel bearings are used to transfer rotational force through a carrier; this position causes the entire weight of the vehicle to be distributed among the wheel bearings. The constant pressure caused by the weight of the vehicle combined with the rotational movement of the bearing and the intense impacts sustained by off-road vehicles all contribute to shortening the service life of a wheel bearing.

While dust and debris can significantly shorten the service life of a wheel bearing, the oil seals included with many wheel bearing kits have no impact on transfer of motion.

Maintenance Costs

Wheel bearings are a very common wear item and should be checked often. Due to the location inside the steering knuckle, worn wheel bearings can cause significant damage to nearby parts such as the steering knuckle, wheel bearing spacers, wheel hubs, and in some cases even rotors.

It is not recommended to replace wheel bearings with previously used bearings. Fortunately, wheel bearings are easy to inspect. With the wheel lifted off the ground, the wheel bearings can be examined by grabbing the tire on both sides and attempting to pull the tire with one hand while simultaneously pushing with the other. Any free play observed during this motion suggests wheel bearings that are at the end of the service life.

Replacement wheel bearing kits are relatively inexpensive - because wheel bearing kits vary by make and model as well as bearing manufacturer’s, they are available in a wide price range. An acceptable price for an aftermarket wheel bearing replacement kit falls anywhere between $15 for a single wheel bearing with no oil seal capable of replacing wheel bearings on a single wheel to $45 for a dual wheel bearing kit with oil seals capable of replacing both front or rear wheel bearings.

-

Original price $ 159.99 - Original price $ 204.99Original price$ 159.99 - $ 204.99$ 159.99 - $ 204.99Current price $ 159.99

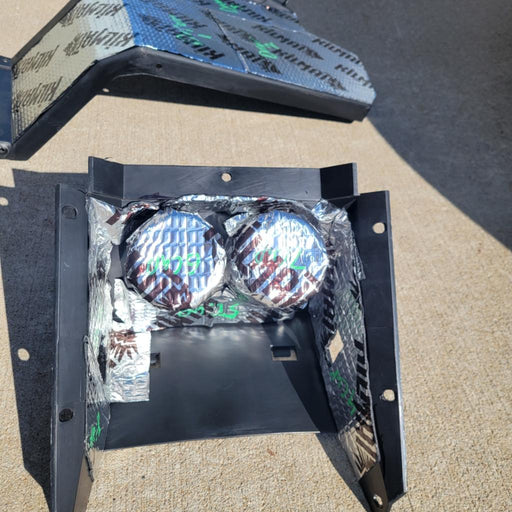

Air Filter Relocation Kit for ODES UTVS

Scooter's PowersportsOut of stockOur very own Air Filter Relocation kit for ODES UTVS. Designed and manufactured by Scooter's Powersports. Unlike some ODES Air Filter Relocation K...

View full detailsOriginal price $ 159.99 - Original price $ 204.99Original price$ 159.99 - $ 204.99$ 159.99 - $ 204.99Current price $ 159.99Sold out -

Original price $ 129.99 - Original price $ 159.99Original price$ 129.99 - $ 159.99$ 129.99 - $ 159.99Current price $ 129.99

Pre-Cut Sound Proof Matting for ODES UTVS

Scooter's PowersportsIf the noise inside the cab of your ODES UTV has ever bothered you, this. is your solution. Now you can get one of our best selling shop services a...

View full detailsOriginal price $ 129.99 - Original price $ 159.99Original price$ 129.99 - $ 159.99$ 129.99 - $ 159.99Current price $ 129.99 -

Original price $ 40.00 - Original price $ 40.00Original price$ 40.00$ 40.00 - $ 40.00Current price $ 40.00

Voltage Regulator Relocation Kit for ODES UTVS

Scooter's PowersportsDesigned to move the voltage regulator from under the hood to under the seat. Requested by you and built by Scooter's Powersports. Allows for elimi...

View full detailsOriginal price $ 40.00 - Original price $ 40.00Original price$ 40.00$ 40.00 - $ 40.00Current price $ 40.00 -

View all ODES UTV Performance mods

View all ODES UTV Performance mods

-

ODES UTVS best sellers

ODES UTVS best sellers -

Original price $ 38.49 - Original price $ 55.99Original price$ 38.49 - $ 55.99$ 38.49 - $ 55.99Current price $ 38.49

ODES Oil Change Kit for 800 and 1000 Engines

Scooter's PowersportsODES Industries recommends an engine oil change at 25-hours of run time or 1000 miles. (We won’t tell if you turn that down to once every 50-hours ...

View full detailsOriginal price $ 38.49 - Original price $ 55.99Original price$ 38.49 - $ 55.99$ 38.49 - $ 55.99Current price $ 38.49 -

Original price $ 7.99 - Original price $ 7.99Original price$ 7.99$ 7.99 - $ 7.99Current price $ 7.99

ODES Oil Filter - High-Performance

Not specifiedHigh-performance aftermarket ODES oil filter. Compatible with 800cc and 1000cc ODES engines. Be sure to select your make and model before adding to...

View full detailsOriginal price $ 7.99 - Original price $ 7.99Original price$ 7.99$ 7.99 - $ 7.99Current price $ 7.99 -

Original price $ 49.99 - Original price $ 62.00Original price$ 49.99 - $ 62.00$ 49.99 - $ 62.00Current price $ 49.99

Pivot Works Wheel Bearing Kit for ODES - Lifetime Replacement!

Pivot WorksPivot Works wheel bearing kit for 2012+ 800cc and 1000cc UTVs from ODES Industries. Fitment includes the Short Travel (Standard) suspension and the...

View full detailsOriginal price $ 49.99 - Original price $ 62.00Original price$ 49.99 - $ 62.00$ 49.99 - $ 62.00Current price $ 49.99 -

Original price $ 159.99 - Original price $ 204.99Original price$ 159.99 - $ 204.99$ 159.99 - $ 204.99Current price $ 159.99

Air Filter Relocation Kit for ODES UTVS

Scooter's PowersportsOut of stockOur very own Air Filter Relocation kit for ODES UTVS. Designed and manufactured by Scooter's Powersports. Unlike some ODES Air Filter Relocation K...

View full detailsOriginal price $ 159.99 - Original price $ 204.99Original price$ 159.99 - $ 204.99$ 159.99 - $ 204.99Current price $ 159.99Sold out -

Original price $ 40.99Original price $ 40.99 - Original price $ 40.99Original price $ 40.99Current price $ 36.95$ 36.95 - $ 36.95Current price $ 36.95

ODES 800cc Air Filter | 21040401001

ODES IndustriesOut of stockOEM air filter for ODES 800cc engines. Vehicle Fitment This part is compatible with the following vehicles 2012+ ODES Dominator 800 2015+ ODES Dom...

View full detailsOriginal price $ 40.99Original price $ 40.99 - Original price $ 40.99Original price $ 40.99Current price $ 36.95$ 36.95 - $ 36.95Current price $ 36.95Sold out -

Original price $ 18.99 - Original price $ 18.99Original price$ 18.99$ 18.99 - $ 18.99Current price $ 18.99

Fast Boot Kit

MooseOut of stockExtremely heavy duty CV boot that fits virtually all ATVs and UTVs. Additional rib to allow boot to expand for larger joints Improved clamp retain...

View full detailsOriginal price $ 18.99 - Original price $ 18.99Original price$ 18.99$ 18.99 - $ 18.99Current price $ 18.99Sold out -

Original price $ 29.99 - Original price $ 29.99Original price$ 29.99$ 29.99 - $ 29.99Current price $ 29.99

ODES Ball Joint Kit

Scooter's PowersportsODES ball joint kit for 800cc and 1000cc ODES UTVs. ODES Ball Joint Kit Includes (1) Ball joint (1) Circlip (1) Cotter pin (1) Nut Each kit provi...

View full detailsOriginal price $ 29.99 - Original price $ 29.99Original price$ 29.99$ 29.99 - $ 29.99Current price $ 29.99